Setting up

and adjusting SU/Hitachi carbs on the Datsun Roadster

by Keith Williams

First things first.

In order for the carbs to work

properly the ignition timing and valve clearance must be correct.

On the 1600 (R16) engine two

different distributors were used. The point gap for both is .018" to

.022" or .45mm to .55mm. The dwell angle for the

The 1600 (R16) was fitted with

the early mechanical advance curve of 15 crank degrees and a late (smog) 30

degree curve. The early distributor requires an initial timing setting of 16

degrees before top dead center. The late distributor is set to zero degrees

before top dead center. Distributors were often swapped so it is best to check

to see which on is in your car. A way to do that is, after disconnecting the

vacuum advance, set the timing to TDC. Rev up the engine watching the timing mark.

The early distributor will only advance 15 degrees. The later will advance 30

degrees. For a final check after setting the timing hook up the vacuum advance,

rev up the engine and check the total advance. It should be about 36 degrees

maximum. On the SU equipped 2000(U20) the timing should be set to 16 degrees

BTDC.

Valve adjustment is very

important. The amount of fuel/air mixture each cylinder draws is affected by

when the valves open and close and that is affected by the clearance setting.

For the 1600(R16) all valves ate set to .017" or .43mm with the engine

warmed up. The 2000(U20) intake valves are set to .008" or .2mm and the

exhaust to .012" or .3mm. Again with the engine warmed up.

Insure that there is some

slack in the throttle cable. The cable housing grows longer as it heats up. If

there is not enough slack the idle speed will get higher as the engine warms

up.

Service screw?

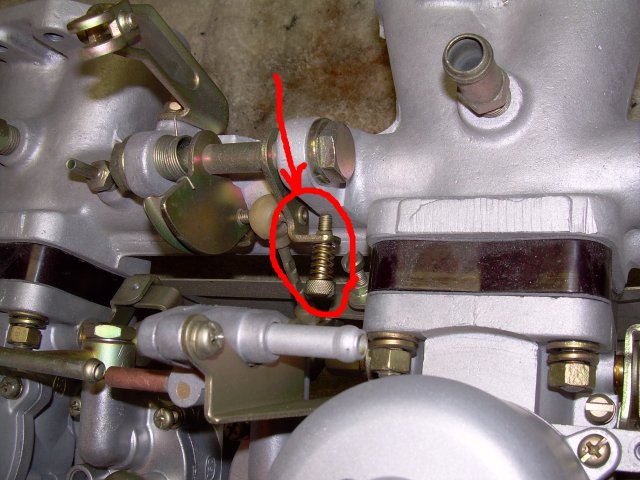

This is the “service screw”

it’s only use it to raise the engine speed while adjusting the carbs. In normal

operation it is backed off till it does not touch.

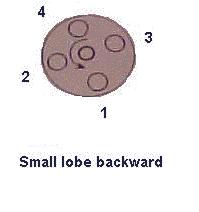

The service screw found on the 1600

(R16).

This service screw design was

introduced with the 67.5 2000. This engine did not have the thermo fuel valve

and the design worked well. In 1968 the thermo fuel valve was introduced and

there is an interference problem between the screw and the valve. Some of the

screws were made shorter to address this problem. The shorter screws are too

short to work properly. A small folded up piece of paper between the screw and the

manifold will allow it to work. When you are done using the screw it needs to

be screwed in as far as it will go without touching the manifold and the screw

head to thermo valve clearance checked. If they hit it can cause the throttle

to stick open.

Idle air flow synchronization

With the service screw backed

off and some slack in the throttle cable the dog bones should have some play.

This looseness allows the idle adjustment screws to control the throttle

butterfly valves. If either throttle is being pushed closed or pulled open by

the dog bone at idle, adjust the length of the dog bone.

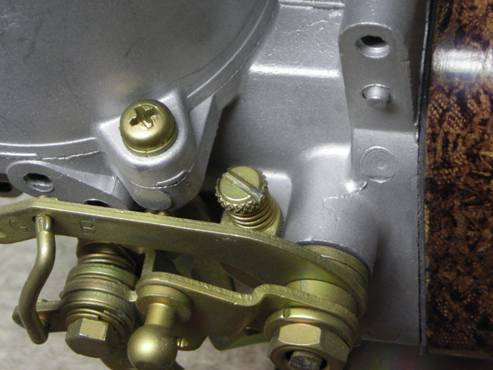

Here is the front carb idle air flow adjustment screw for the

1600. This screw opens the butterfly valve a small amount.

The 1600 rear carb idle air

flow adjustment screw is the same as the front. If the dog bones are set up

properly and the service screw is backed off the two idle adjustments should

act independently.

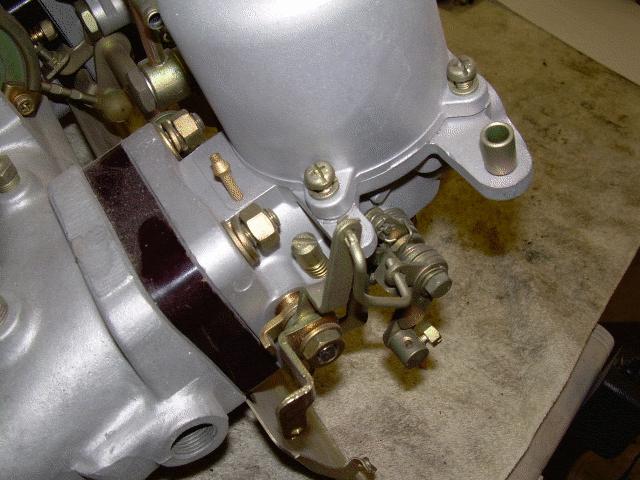

The 2000 idle adjust screws. The 2000 carbs are mirror image of each other

so the screws are on the opposite side.

Front 2000 carb idle adjustment

Rear 2000 carb idle adjustment

High speed air flow

synchronization

Here is the "dog

bone", the 1600 has two of these turnbuckles to adjust the high speed

synchronization of the carbs.

The "dog bones" are

turnbuckles. It is not necessary to remove them to change the length. Loosen

both lock nuts and turn the center section to vary the length. After the

initial setup is done pick one dogbone to make future adjustments. This

prevents them from getting progressively longer or shorter as you switch back

and forth. I normally adjust the one closest to the firewall.

The high speed

synchronization screw on the 2000 carbs. This screw should be a very snug fit

to prevent it from moving from vibration. A properly fitting screw driver is

essential.

Air flow balancing.

By measuring the air flow through each

carb with a UNI-SYN or similar tool the front and rear air flows are set to be

the same.

This is the UNI-SYN. A good basic tool

that gets the job done.

The idle air flow is balanced

first. The Uni-Syn is adjusted so that the ball rises about half way up the

tube. By adjusting the idle speed screws

the idle speed is maintained about 600-700 RPM and the flow is adjusted so that

the ball raises the same on both carbs.

Once the idle air flow is

balanced the service screw is used to raise the engine speed to 2000 RPM. The

Uni-Syn is adjusted so that the ball rises about half way up the tube at this

higher speed. Using the dogbone on the 1600 or the balance screw on the 2000

the flow is balanced so that the ball raises the same amount on both carbs.

When the high speed is

balanced, back off the service screw and recheck the idle air balance. The two

adjustments should be independent but sometimes it takes a little fiddling to

get all the linkages set up properly.

Mixture adjustment

Once everything else is done it is time to adjust the fuel/air mixture. The

mixture adjustment is done with the large knobs on the bottom of the carbs.

This knob raises and lowers the metering

nozzle. Screwing the knob down (clockwise from the top of the carb) lowers the

nozzle and richens the mixture. Turning the knob up (anticlockwise from the top

of the carb) raises the nozzle and leans the mixture.

To set the carb mixtures first raise the engine speed to 2000 RPM with the

service screw. The idle and high speed mixture both are set with the same knob.

As the car is usually driven with the engine at speed and spends little time at

idle I prefer to set the mixture at the higher speed. There are two methods to

set the mixture knobs. The first is to use a service tach to monitor the engine

speed. Adjust each carbs mixture knob to maximize the engine RPM. If the engine

speeds up too much lower the speed with the service screw. The other is to

raise and lower the slides to test the mixture. Reach down the carb mouth and

lift the slide a little with your fingernail. Try to stay out of the air flow

going under the piston. Raising the piston allows more air in and reduces the

vacuum at the nozzle. This leans this carb. If the engine speed rises as the

slide is raised a little that carb is rich. The adjustment knob for that carb

needs to be turned up (anticlockwise). With a little practice you can push down

on the face of the slide and lower it a little. This reduces the air and

increases the vacuum at the nozzle. This richens the carb. If the engine speeds

up that carb is lean. The adjustment knob needs to be turned down (clockwise).

Once the mixture is correct either raising or lowering the slide will slow the

engine speed. With either method this will get you very close to the ideal

mixture. This is where the idle speed is adjusted to be between 600 and 700

RPM. Remember, to raise or lower the idle speed both adjustment screws need to

be changed and the air flow rebalanced. Once this is done recheck the high and

low speed air flow balance. For the final adjustment the car needs to be driven

and the spark plugs checked. Starting with fresh plugs. If the plugs are getting

black from carbon that carb is a little rich. Lean it about 1/4 turn. If at a

constant throttle cruise you notice stumbling the carbs are too lean. Richen

both about 1/4 turn. A couple of rounds of this and you should get rid of

stumbling and not carbon the plugs.

Dashpot

Oil

On

acceleration the mixture needs to be richer or you will get stumbling. The oil

in the dash pot slows the rise of the piston. The piston being lower than it wants

to be causes the mixture to be rich. Generally speaking you want to use the

thinnest oil that stops stumbling on acceleration. Roadsters tend to be quite

tolerant of running rich so thicker is better than thinner. However, too thick

will over richen and cause the acceleration to feel flat. The correct thickness

will have a crisp acceleration. The factory spec is 10w. That is in the range

of ATF and MMO. 3 in 1 is thinner. In one Z I did I ended up with 50w before it

would accelerate cleanly. The synthetic oils do tend to be thinner than regular

oils so I'm not sure what the "real" viscosity of the synthetic is.

Motorcycle fork oil works well, comes in convenient bottles, and in lots of

weights. Single weight engine oil comes in 20, 30, 40, and 50 weight but I

haven't seen 10w. If you're being fiddly you can mix weights to come up with in

between weights. I use fork oil for the thinner weights and single weight

engine for the thicker.

Common problems

Mixture knob all the way lean and the

carb still too rich:

The most common cause is worn metering needle or nozzle. The metering needle

should have a satin finish. Shiny spots indicate wear and the needle should be

replaced. The hole in the end of the nozzle should be round. It is .092"

for the 1600 and .100" for the 2000. They can be checked with a pin gauge.

If visibly pear shaped or worn oversize it must be replaced.

Another possibility is the float level being too high. If you remove the dome

and piston immediately after the engine is shut down the fuel level should be

down the nozzle a little bit. When the choke is pulled full on the end of the

nozzle should be lowered just below the fuel level. This will cause a small

puddle of gas on top of the nozzle. If the fuel level is higher than the top of

the nozzle with the choke off that carb will always run very rich.

Choke sticking:

If the choke linkage is sticking the nozzle can stay down when the choke is

off. The best way to clean the linkage is with a good quality spray carb

cleaner. Lubrication of the carb linkage should only be done with silicone

spray. WD-40 and similar products leave a sticky residue that collect dirt and

make things worse. The float bowl to nozzle hose must be flexible. If it is

hard and stiff it needs to be replaced.

High speed mixture good but idle way too rich:

This is an indication of worn metering needles and nozzles. Check the needles

and nozzles for wear. The Nissan metering needles for the 1600 tend to be rich

at idle and lean through the mid range. As they wear this only gets worse. My

prefered needle for the 1600 is the British ADQ needle. They were not fit to

cars that came to the

Where does the vacuum advance from the

distributor go?

The roadster uses ported

vacuum from the carbs to operate the vacuum advance. This provides no advance

at idle, maximum advance off idle and at cruise, and little of no advance at

wide open throttle. The 1600 vacuum port is on the bottom of the rear carb. The

2000 vacuum port is usually on the top of the front carb but can sometimes be

found on the top of the back carb. The hose barb on the manifold is for emission

controls. If this port is used for the distributor vacuum advance the advance

will be maximum at idle. This increases the idle speed making setting the carbs

difficult.

A

method to fine tune the idle mixture

The metering needle can be set out from the piston a few thousanths of an inch

to lean the idle mixture. This effects the high speed mixture some but the

major effect is on the idle mixture. By setting the needle out a little at a

time and checking the idle and high speed mixture both can be dialed in. This

is not a fix for worn needles and nozzles as it will only move the too rich

condition to just off idle.

Metering needles for the 2000 SU carbs

I have found a selection of

metering needles that provide a good range of options for the 2L engine. The

baseline on this graph is the stock Nissan N-17 needle. Up is richer and down

is leaner. All the needles start out

about the same place at idle but are progressively richer as the engine load

goes up. The N-17 will sometimes be too lean at the top end if modifications

have been made to the engine. The normal approach is to step through the

selection in lean to rich order (MC, KW, RB, RA) until you find what your

engine likes. These are British SU

needles and are available through Burlen Fuel Systems in

Nissan part numbers

for some carb items

These parts are available

through Nissan as of the last time I checked. They often are not happy about

looking them up. But, if you bring the numbers they will usually order them for

you.

Loose floats for 1600s and

some 2000s 16061-K1407

1600 manifold gasket 14035-14611

Carb Gasket kit, includes

float bowl gasket 16455-H2310

Hinged floats for most 2000s

and some 1600s 16061-E4310

N-17 metering needles, stock

for 2000s 16354-25611

2000 manifold gasket 14035-25501

Float bowl gasket only 16064-22010

Here is the instruction sheet from

the 240Z three screw Hitachi S.U. carb rebuild kit. This is most like the 2000

carbs. Some of the details vary from the

Roadster carbs but the overall principles are the same. Of particular interest is the chart for

setting the mixture knob for altitude and temperature. Also, for this carb they

recommend 20w oil, the roadster uses 10w.

And that pretty much covers

adjusting the SU carbs on a Datsun Roadster. They are a fairly simple design

and pretty rock solid once dialed in. Thanks to Keith for sharing his

expertise.

last updated 10/31/08 8:10am

Copyright

(c) 2001-2008 www.311s.org

All Rights Reserved.

Reproduction of material presented here is strictly prohibited without

written permission from the Author.